Welcome

The primary challenge in adopting « Big Data » Analytics is its need for extensive data and infrastructure, making it complex, expensive, and suited only for server-based or cloud architectures with adequate resources. Leveraged on the advanced concept of PIML DeepPhy develops AI solutions that operates efficiently with limited data. This technology powers Digital Twins, evolving computational models that accurately reflect and inform about unique physical assets, driving valuable decision-making.

OUR SOLUTIONS

Predictive engineering

By design, DeepPhy solutions enable physically consistent generalization beyond your dataset. These solutions allow accurate simulations and informed decision-making, ultimately driving efficiency and innovation in engineering industries.

Examples: Materials and Structural Analysis, Optimized Product Design, Virtual Prototype Simulation, Energy Management ,…

Risk management and prevention

Risk management and prevention strategies proactively identify, assess, and mitigate potential risks. These solutions combine data analysis, predictive modeling, and strategic planning to minimize vulnerabilities and enhance resilience.

Examples: Occupational Safety, Quality Control, Environmental Risk Assessment, Supply Chain Risk Management,…

Predictive maintenance

Predictive maintenance solutions utilize advanced analytics and machine learning to forecast equipment and machinery maintenance needs. By analyzing historical data and real-time performance indicators, these solutions can detect potential issues before they cause costly breakdowns, enabling businesses to schedule maintenance proactively.

Examples: Supply Chain Optimization, Infrastructure Monitoring, HVAC Systems…

About us

The DeepPhy start-up was created in 2023 by Yoann Cheny (CEO) and Mickaël Delcey (CTO), two researchers from the University of Lorraine with a recognized expertise in engineering sciences and artificial intelligence. DeepPhy offers now AI solutions for engineering sciences stemming from over 10 years of research in the field.

A Word from the director :

« Our team is a dynamic fusion of passionate AI enthusiasts with expertise spanning physics, fluid mechanics, Rheology, machine learning, and CFD. Each member brings a unique skill set, from mastering physical principles to simulations using IA. We also excel in extracting insights from complex data using advanced machine learning algorithms and creating true-to-life virtual models for predictive solutions. Together, we are a creative team dedicated to pushing the boundaries of innovation and turning ideas into reality «

Our mission : At DeepPhy, our mission revolves around putting our customers at the forefront. We are dedicated to assisting our customers in their research and production endeavors, specifically in the realm of AI solutions. We are a team of AI experts, continuously seeking to incorporate customer insights into refining our solutions. Our commitment lies in the development of superior solutions that enhance lives while upholding environmental responsibility. As technology enablers, we have deliberately chosen to collaborate with top-tier companies, delivering enduring value through cutting-edge tools designed for long-term impact. We place a strong emphasis on attentive listening to our customers’ needs to ensure their satisfaction.

Technology

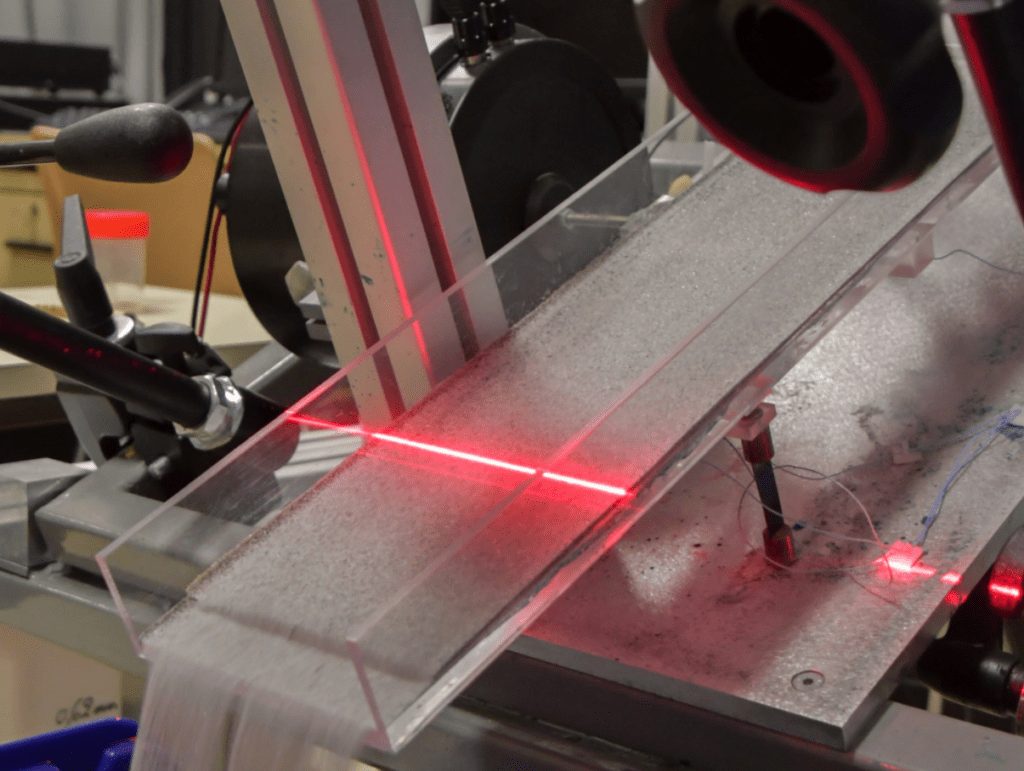

Pinns

Imagine a tool that revolutionizes the industry, combining the power of artificial intelligence with the precision of physical laws. That’s exactly what Physics-Informed Neural Networks (PINNS) bring to the industry. These neural networks incorporate fundamental physical principles into their learning, meaning they not only understand data but also the laws that govern the real world. With PINNS, businesses can predict complex system behavior with exceptional accuracy, optimize manufacturing processes, anticipate equipment breakdowns, and design high-performing products. It’s a revolutionary breakthrough that reduces costs, enhances efficiency, and fuels innovation.

PINNS represent the new frontier of AI for industry, offering an invaluable competitive advantage. Don’t miss this opportunity to revolutionize your business with this cutting-edge technology

One example: ventilation in buildings or Heating, Ventilation, and Air Conditioning (HVAC) systems.

1. Modeling Air Behavior: PINNs can be trained to model the behavior of air inside a given space. They can take into account physical factors such as air circulation, temperature, humidity, pressure, and room geometry.

2. Optimizing Ventilation System Design: PINNs can be used to optimize the design of the ventilation system. For example, by analyzing the performance of different duct designs, air grilles, and filtration systems, PINNs can help design a more efficient and energy-efficient ventilation system.

3. Real-time Air Quality Monitoring: PINNs can be integrated into air quality monitoring systems. By analyzing real-time data, they can detect changes in air quality, such as the presence of pollutants or contaminants, and recommend adjustments to ventilation systems to maintain a healthy environment.

4. Predictive Maintenance for Ventilation Systems: PINNs can predict maintenance needs for ventilation system components, such as fans, filters, and control systems. This allows for proactive maintenance planning to minimize unexpected downtime.

5. Energy Consumption Optimization: By analyzing operating data from the ventilation system, PINNs can recommend adjustments to optimize energy consumption while maintaining adequate comfort levels.

Digital Twins: Revolutionizing Industry with Virtual Mirrors

Digital twins are emerging as a transformative technology, bridging the physical and digital realms. Essentially, they are virtual replicas of physical objects, processes, or systems, meticulously mirroring their real-world counterparts. These digital twins are imbued with the ability to collect real-time data, simulate behaviors, and provide invaluable insights. In the industrial landscape, digital twins offer a plethora of advantages. They empower organizations to monitor and optimize complex processes with unprecedented precision. From manufacturing lines to power plants, digital twins enable predictive maintenance, identifying issues before they cause costly downtime.

Moreover, digital twins facilitate agile design and prototyping. Engineers can simulate and test new products or systems in a risk-free virtual environment, fine-tuning their performance and efficiency before physical implementation. In the era of the Internet of Things (IoT) and Industry 4.0, digital twins are becoming the backbone of smart factories and cities. They enable real-time monitoring, data-driven decision-making, and efficient resource allocation. Beyond industry, digital twins are making inroads into healthcare, urban planning, and even space exploration, promising innovation and efficiency across various domains. In a world increasingly reliant on data and connectivity, digital twins are at the forefront of the transformative wave, offering a glimpse into a more connected, efficient, and sustainable future. »